Aerospace Industry

As tough as it gets for Surface requirements

Highly efficient, ultrareliable engineering is just one of the challenges the aerospace industry rises to on a regular basis, which is why manufacturers expect their components and production processes to meet such stringent requirements. By 2050, Europe’s ACARE alliance aims to cut carbon dioxide by 75%, nitrogen oxide by 90% and noise by 65%.

A key factor in meeting those targets is to reduce engine friction, which in turn requires smooth functional surfaces.

Efficient design often implies very narrow tolerances and less scope for process variation, making stable, repeatable, fully automated production processes all the more important.

Leading OEM, TIER 1 and TIER 2 manufacturers in the aerospace supply chain rely on our innovative finishing solutions, which far outperform the conventional processes they used in the past.

OTEC’s mass finishing machines are designed for applications ranging from smoothing for minimal roughness (superfinishing or ultrapolishing) to rounding and/or deburring. On request we also develop other, highly customised applications.

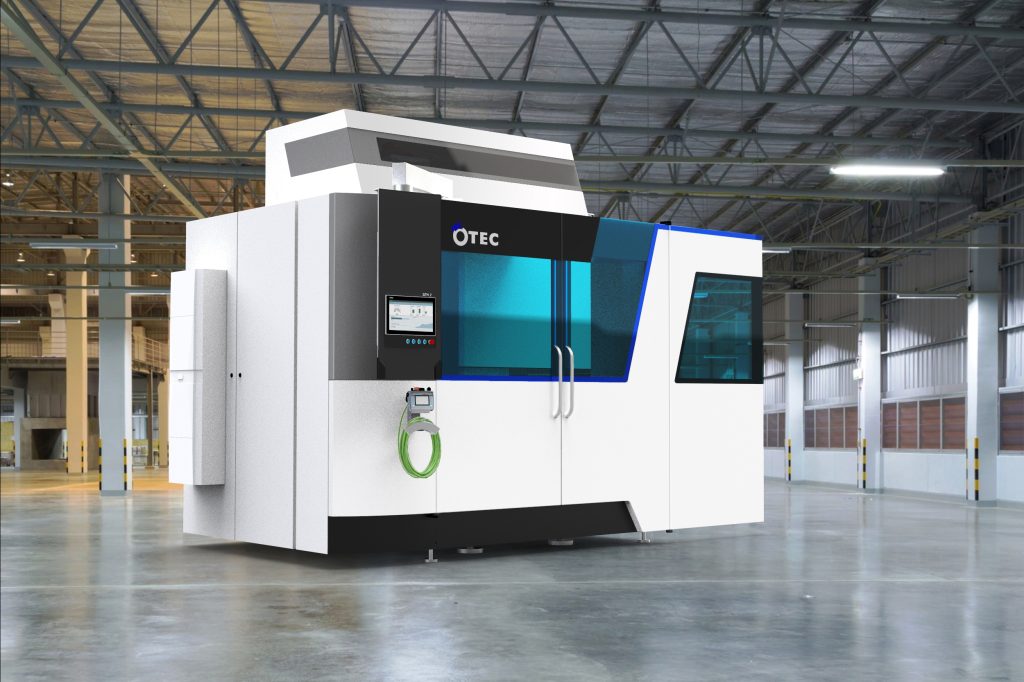

SF HP Series – Our Largest Machine Yet

The SF-HP is the latest member of the SF-Series and the world’s only stream finishing machine for the surface finishing of large and heavy workpieces. With the proven OTEC Streamfinish-DNA!

Like the entire SF-Series, it therefore ensures smoothing, high-gloss polishing, edge rounding and deburring in a single operation, in just a few minutes and without damaging the contours of the workpiece. Due to the path-controlled motion sequence, it is possible to target and process individual areas of a workpiece particularly intensively.

The SF-HP enables extremely fast and economical machining with absolute repeat accuracy due to the high machining forces. The SF-HP offers the most efficient, stable and, at the same time, innovative machining solution compared to conventional processes.

Typical applications for the SF-HP are large and heavy workpieces with a length of up to 650 mm, 900 mm diameter and a weight of 200 kg. Typically, these are workpieces from the aerospace, mechanical engineering, tooling, energy, oil and gas, shipbuilding or food industries.

The OTEC innovation, PULSFINISH, is part of the standard equipment!

The process principle of the patented pulse drive is based on the precisely defined and recurring movement intervals between media and workpiece in short succession. This makes it possible, for example, to deburr, round off and smooth from Rpk 0.3 μm to Rpk 0.1μm in a single work step in just a few minutes. The tribological surface properties are improved, which means friction and wear are reduced.

Additional Aerospace Finishing Offerings:

SF Series

Stream finishing machines with optional pulse finishing, for manual workpiece loading, suitable for e.g. small batches or non-takt production lines.

AUTOMATIC SF SERIES

Stream finishing machines with optional pulse finishing, for automatic workpiece loading, suitable e.g. for takt production lines. Set up for automatic loading or fitted with it as an integrated option.

CF SERIES

Years of experience have gone into our CF Series disc finishing machines, which are designed for rapid, flawless surface processing on bulk parts.

SMOOTHING | POLISHING – STREAM FINISHING | DISC FINISHING

Ultra-smooth surfaces on assemblies such as compressors and gearboxes are indispensable for efficient engine operation. Our customised stream finishing (SF) and disc finishing (CF) processes smooth and polish to Ra 0.01.

With process speeds up to 24 times faster than hard-to-control, chemically accelerated mass finishing, OTEC machines rise to many a challenge not only more quickly but also at lower cost and with greater process reliability. What’s more, they do away with expensive, polluting, dangerous acids and materials.

In industrial manufacturing processes for compressor blades, vanes and blisks, our customers obtain roughnesses of ~Ra 0.15 with systems tailored to their requirements.

Smooth tooth flanks and rounded tip edges boost gearbox efficiency by minimising friction and Rpk values. Another specific of the stream finishing process is that it produces lubrication valleys, significantly reducing the risk of oil film breakage – and therefore wear – to guarantee safe operation. Our stream finishing process obtains roughnesses as low as Ra 0.07 µm on high-grade hardened gears.

DEBURRING | EDGE ROUNDING – STREAM FINISHING | DISC FINISHING

After the primary or shaping manufacturing process, sharp edges, fraying or burrs must be removed from the workpiece. The edges can very often be rounded as required at the same time.

Processes that are tailored to the workpiece allow custom surface processing for bulk materials and piece goods using the OTEC mass finishing machines.

ADVANTAGES OF OTEC’S SURFACE PROCESSING

- Deburring and edge rounding in one process

- Improved handling and fitting

- Reduced risk of injury during assembly

- Components look and feel better