DRAG FINISHING UNITS - DF SERIES

Custom-designed work piece holders make a significant contribution to the perfect processing results obtained by the DF series. They also ensure that the work pieces are mounted as quickly and efficiently as possible and considerably simplify batch processing. In recent years, OTEC has designed over 100 different types of holder. Furthermore, the process container features a water-cooling system that keeps the polishing granulates at a constantly low temperature. This considerably extends the life of the process medium and ensures constant process quality, even at consistently high processing speeds.

Absolute reliability

- Consistent use of only the best materials and components ensures trouble-free operation and long service life.

Maximum cost-effectiveness

- Comparatively low capital investment coupled with the potential for very high cost savings in terms of processing times make the DF series an extremely cost-effective solution.

Perfect finishing results

- Deburring, grinding or high-luster finish in a quality otherwise only obtained through hand polishing.

Short processing time

- In many cases, perfect surfaces can be obtained in just a few minutes.

SERIE DF “WET” SERIES

Drag finishing machine for mass finishing and polishing of knee and hip joints, burr shafts, watch cases, dies, pistons and decorative work pieces.

STANDARD EQUIPMENT

- Process drum coated with PU to reduce wea

- High-quality sealed cladding in stee

- Flow-optimized process containe

- Vertical spindle with ball screw drive for 90% on-tim

- Display and selection of vertical work piece positio

- Infinitely variable drag finishing speed via frequency inverte

- Storage capacity for up to 200 process configuration

- Generous clearance between container rim and holder makes it easier to fit work pieces to holder

- Bearings for work piece holders of up to 15 kg

- Process data can be backed up onto external MMC card

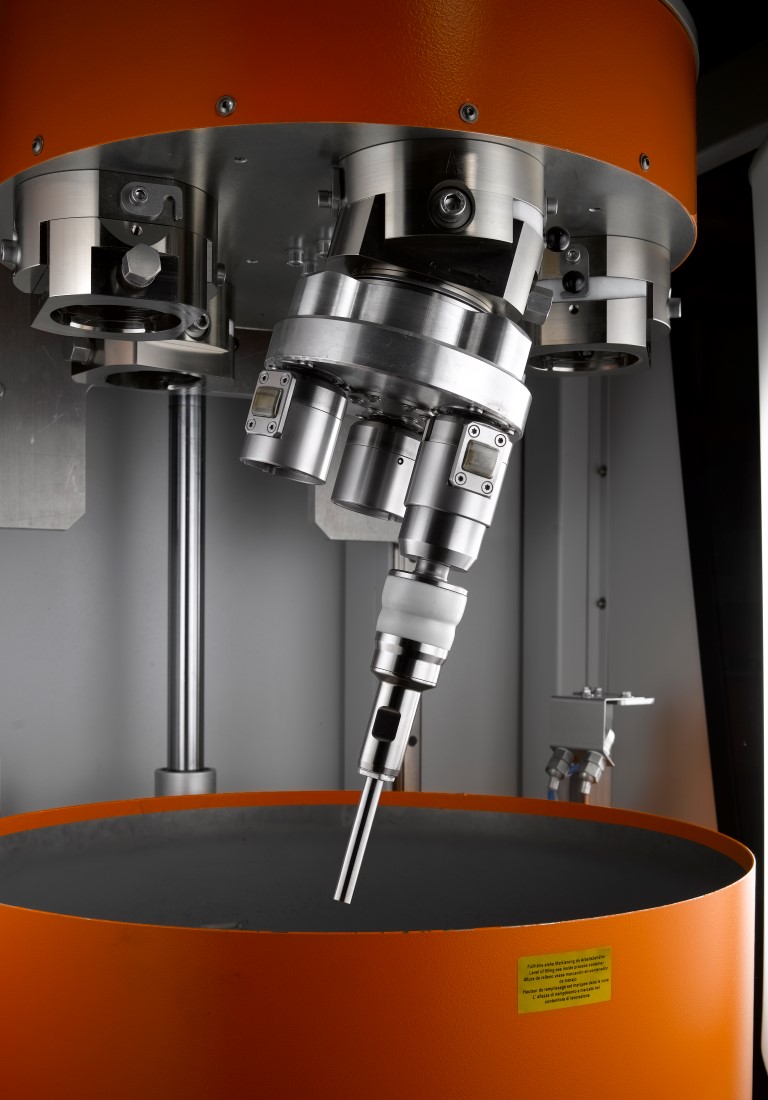

DF-3/4 TOOLS SERIES

Drag-finishing machine for cutting tools and other large work pieces

STANDARD EQUIPMENT

- Process container with a capacity of 88 l

- Sturdy chassis made from 50 x 100 mm aluminum profile

- High-quality, sealed cladding in steel, exterior of panels and base painted

- Flow-optimized octagonal process container

- Vertical spindle with ball screw drive for 90% on-time

- Vertical work piece position display and pre-selection

- Storage capacity for 200 process configurations

- Greater clearance between container rim and holder makes it easier to fit work pieces to holders

- 3 or 4 clamping devices for the work piece holders

- Stronger bearings for holding weights of up to 15 kg

- Process data can be backed up onto external MMC card

- Additional drive unit for independent holder rotation and higher speeds

DF-5/6 TOOLS SERIES

Drag finishing machine for cutting tools and other large work pieces

STANDARD EQUIPMENT

- Process container with a capacity of 114 liter

- High-quality, sealed cladding in steel, exterior of panels and base painted

- Flow-optimized octagonal process container

- Vertical spindle with ball screw drive for 90% on-time

- Vertical work piece position display and pre-selection

- Storage capacity for 200 process configurations

- Greater clearance between container rim and holder makes it easier to fit work pieces to holders

- 5 or 6 clamping devices for the work piece holders

- Stronger bearings for holding weights of up to 15 kg

- Process data can be backed up onto external MMC card

- Additional drive unit for independent holder rotation and higher speeds

DF-10 TOOLS SERIES

Drag finishing machine for cutting tools and other large work pieces

STANDARD EQUIPMENT

- Process container with a capacity of 170l

- High-quality, sealed cladding in steel, exterior of panels and base painted

- Flow-optimized octagonal process container

- Vertical spindle with ball screw drive for 90% on-time

- Vertical work piece position display and pre-selection

- Storage capacity for 200 process configurations

- Greater clearance between container rim and holder makes it easier to fit work pieces to holders

- 5 or 6 clamping devices for the work piece holders

- Stronger bearings for holding weights of up to 15 kg

- Process data can be backed up onto external MMC card

Holder

INDEPENDENTLY DRIVEN TOOL HOLDERS

With this type of holder specially developed for finishing tools, each work piece rotates individually on its own axis in addition to the general rotation. This produces a uniform surface finish in even shorter processing times. It also achieves excellent smoothing of the flutes of cutting tools.

QUICK TOOL CHANGER

This system enables tools such as drills and burs to be changed in seconds by means of a lever.

ANGLED HOLDER

Especially suitable for finishing end faces and forging dies.

Trolley

TROLLEY FOR DF TOOLS

Trolley with castors for quick container change

Miscellaneous

IMMERSION DEPTH CONTROL

For controlling the depth to which the work pieces are immersed in the granulate. Two photoelectric barriers are used to identify the tip of the work pieces when they are immersed in the medium. From this, the control system then calculates the maximum possible immersion depth. The immersion depth of the work pieces in the process container is displayed for any defined level of medium. The immersion depth of the work pieces can be preselected for best results.

HOOD

Hood for connecting an extraction unit

WATER COOLING

To reduce the temperature of the granulate