ELECTRO FINISHING UNITS

Electro Finishing is an electrochemical material removal process for metallic work pieces using an external source of electric current. It is used to polish, passivate and deburr surfaces. During this process, material is removed from the work piece (anode), which is immersed in an electrolyte specially suited to this particular metal, thereby considerably reducing the surface roughness. The advantages of electropolishing are:

- A metallically pure surface

- No effect on crystalline structure

- Improved resistance to corrosion

- A lasting surface shine

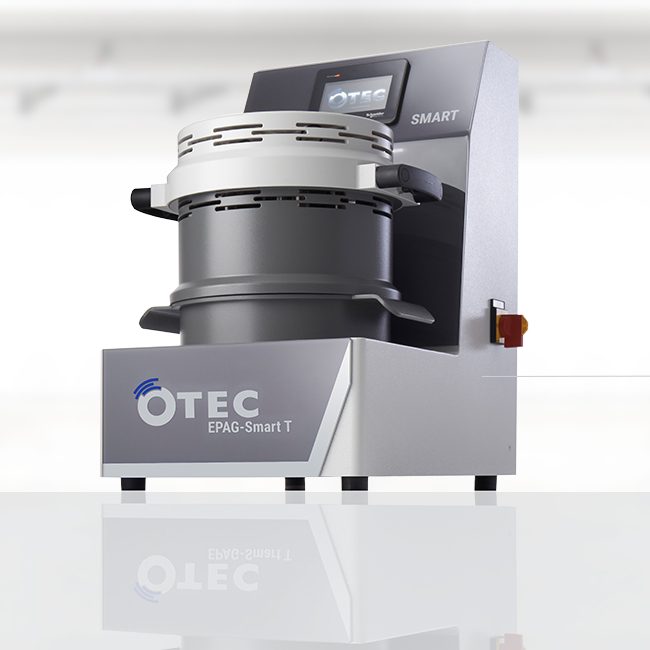

EF-Smart T | Dental

Machine for smoothing and polishing cobalt chrome removable partial dentures and crowns.

EF-Smart S | JEWELRY

Machine for smoothing and polishing gold and silver work pieces.

EF-Nova | Jewelery

This machine combines precision, sustainability, and automation in a compact, affordable system – ideal for small and medium-sized jewelry workshops.

EF-One

Machine for dental and orthodontic laboratories with a compact design and outstanding price-performance ratio make it easy for small businesses to enter the world of automated surface finishing.

EF-Performance

A machine that combines Electro Finishing Technology with established mass finishing technology from OTEC delivers high-gloss perfection for workpieces with complex geometries in diverse sectors.