There are numerous methods and processes available for post processing industrially manufactured metal components, with various advantages and drawbacks depending on the size, geometry, material and finishing requirements. Below we’ll compare several established processes for finishing gear wheels and assess them in terms of health and safety, environmental impact and cost-effectiveness.

Read moreOTEC Stream Finishing For High Output Punching Dies

Punching dies, like all other punching tools, must meet high demands. A punching die’s surface quality is essential for smooth and efficient stamping, which is why the surface processing methods for these tools are constantly being refined. OTEC offers stream finishing machines and process technology for efficient and optimal surface processing of punching dies.

Stream Finishing For Skiving Cutters

Skiving cutters are used in the production of gear wheels. When producing gear wheels, the desired geometry is achieved by a process known as gear skiving, which combines the two traditional processes of gear hobbing and gear shaping. Skiving offers a high degree of productivity and flexibility, and compensates for the drawbacks of the two traditional processes. Compared to gear shaping, gear skiving significantly reduces processing time. With gear skiving, the axes of the workpiece and tool are not parallel but intersect at an angle. Productivity is proportional to the angle of intersection. When the tool rolls off the workpiece, the relative movement created by this angle is used to achieve the cutting speed. The high relative speeds place great demands on the machine technology used and the spindles of the tool and the workpiece must be synchronized. As an industrial application, skiving has been used for more than a century, but it has taken the development of stable and fully synchronized machines to realize its full potential. Surface treatment is essential to enhance the precision and durability demanded of modern skiving cutters and make the process more efficient.

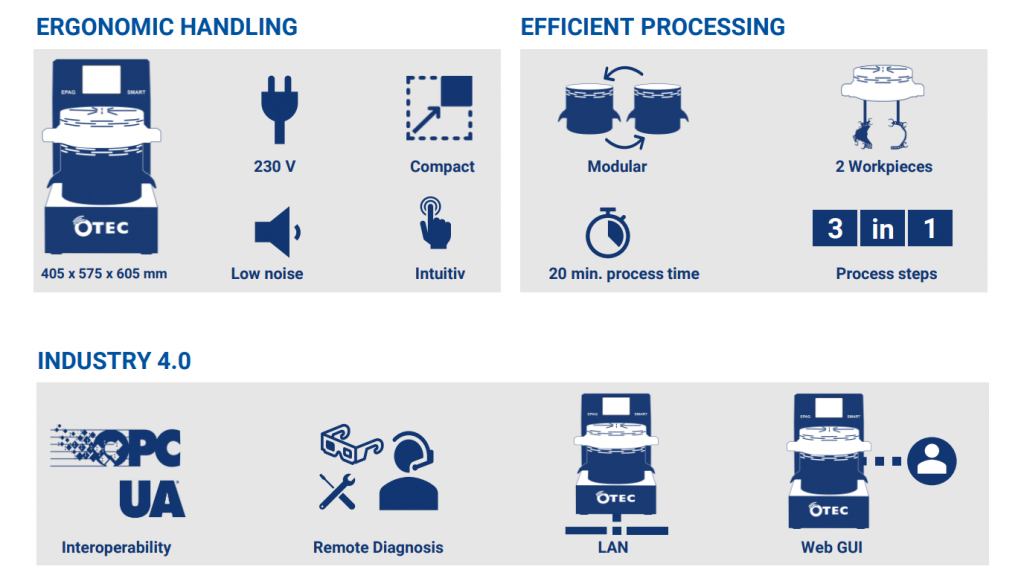

Read moreOTEC’s EPAG-Smart: The Ideal Solution for Dental Laboratories

OTEC’s compact electropolishing machine the EPAG-Smart is capable of perfectly smoothing and polishing dental parts in just one step. It’s able to remove the smallest of scratch marks and waviness in a repeatable process without compromising tolerances or geometries.

Some of the benefits of OTEC’s EPAG-Smart include:

- Homogeneous processing even on geometries that are difficult to access

- No deformation because of the single part processing

- Automation reduces processing work by up to 80%

- No compromise on tolerances or geometries

- Repeatable processes

- Combines multiple steps into one process

- Very efficient in terms of processing time and cost

Contact us today to request sample processing of your dental parts.

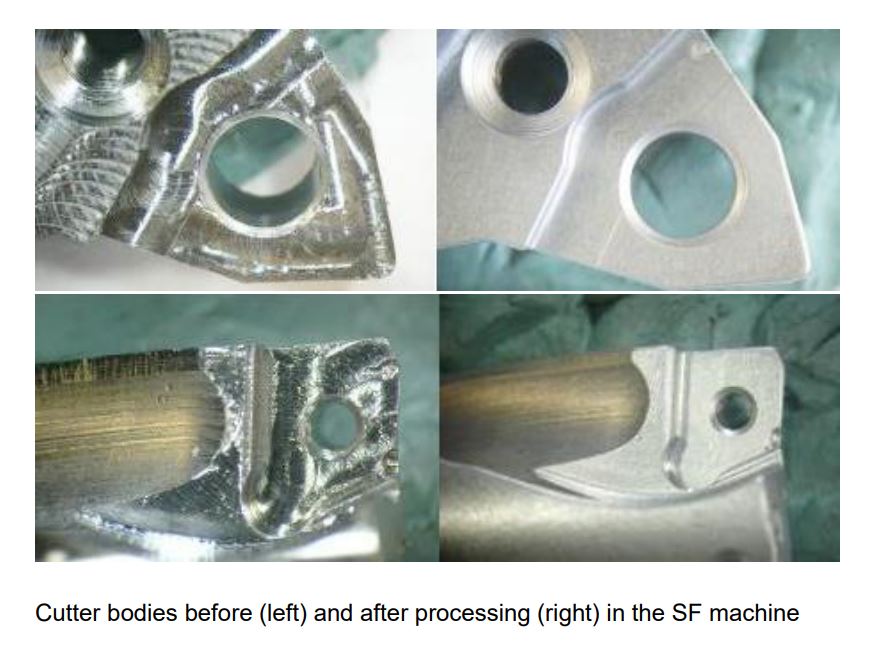

Create Perfectly Deburred and Polished Cutter Bodies With OTEC’s Stream Finishing Machines

Cutter bodies such as drilling, milling and rotary bodies are used for machining processes and serve as holders for inserts. Cutter bodies are available in different lengths and shapes and are manufactured of hardenable steel from which the cutter body is first milled, then deburred, hardened and ground to size. Finally, the polishing or coating of the surface follows e.g. with hard chrome. The coating is intended to prevent corrosion, but is quickly removed by the chips produced during cutting.

The deburring and polishing of cutter bodies has usually been carried out by brushing or blasting. The results obtained using this method are often inconsistent and inaccurate. For instance, if the contact surface for the insert is not absolutely flat, it will have a negative impact on the cutting process itself. Additionally, non-removed burrs can affect the stability during the cutting process. With OTEC’s SF series of stream finishing machines, tool bodies can be perfectly deburred and polished with repeatable and reliable results. In contrast to manual machining, OTEC’s stream finishing machines deliver consistently perfect results. Depending on the initial quality and the size of the workpieces, the typical processing times for polishing are between five to eight minutes. Thanks to OTEC’s patented pulse finishing technology, it’s possible to reduce an initial roughness from Ra 0.2 – 0.5 µm to Ra 0.03 – 0.05 µm.

For surface processing, two main tasks are involved in the production of cutter bodies: Deburring after milling and polishing after hardening and grinding. The reliable removal of burrs is important for optimum fit of the inserts on the cutter body. A burr-free and flat support surface is important for stability during the cutting process and prevents chipping of the insert. The subsequent polish removes the oxide layer formed during hardening, thereby improving the visual appearance and upgrading the part for sale. The perfectly polished, smooth surface not only affects the appearance of the tool but also the functionality. Due to the polish, the surface is closed, compacted and significantly smoothed. The extreme smoothness offers less attack surface for corrosion and ensures a better chip flow in the flute. A specific surface treatment can thus significantly increase the efficiency of the cutter tool.

To learn more about OTEC’s stream finishing machines or request sample processing, contact us today.

Create Custom Processes For Edge Rounding on Carbide Tools With OTEC’s Stream Finishing Machines

OTEC’s stream finishing machines can be used for a range of applications and industries but they offer unique advantages for the toolmaking industry, particularly for edge rounding on carbide tools. Edge rounding or honing carbide tools is a common process that helps extend tool life and improves PVD coating adhesion. Rounding and smoothing the cutting edges of a carbide tool minimizes the risk of microbreakage and also significantly increases mechanical stability.

Many companies have one process for all of their edge rounding needs, which doesn’t always provide the optimal results for all tools. Since professional, high-quality edge rounding depends on a host of factors including application area, material and geometry, using the same process for every tool provides inconsistent and less than optimal results. OTEC’s stream finishing machines allow you to develop custom processes tailored to each tool and then easily automate them.

In order to develop the best edge rounding process, it’s important to consider each tool and what it will be used for and under what production conditions. Each type of tool has its own specifications. In order to guarantee reliable, repeatable, high-quality and cost effective results, a custom process is necessary. As an added bonus, OTEC’s stream finishing machines also allow you to automate these custom processes.

The OTEC SF-1-ILS stream finishing machine is a flexible automated processing solution that you can quickly and reliably tailor to each tool. It allows for automatic retooling for different diameters, with a short process time and high output. With OTEC’s stream finishing machines, heavy, homogenous rounding is attainable and generous immersion depth helps guarantee uniform processing.

Contact us today and we can develop a custom process for your needs.

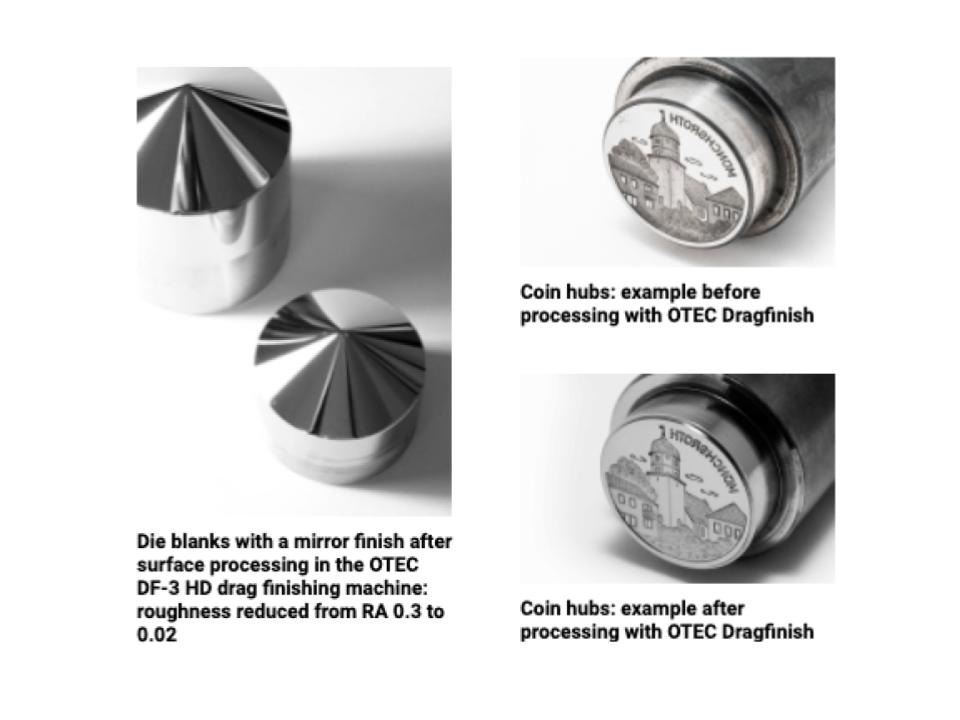

Coin Production With OTEC’s Drag Finishing Machines

Repeatable precision drag finishing is key to producing quality coins and OTEC’s drag finishing machines provide repeatable precision surface processing at two quality-related points in the process of turning metal into money.

Certain parts of the coin production process are frequently done manually, which can be time-consuming and also leads to inconsistent quality since the quality of the finish varies depending on the person working on it. OTEC’s drag finishing machines provide a reliable and cost-effective alternative to manual processing.

OTEC’s DF-3 HD drag finishing machine for wet and dry processing can smooth 12 dies at once in a wet process, then dry and polish them. The advantages of using OTEC’s drag finishing machines to mechanically process engraved hubs are obvious: every hub is exactly the same quality, and lasts longer. Evenly smoothed surfaces reduce friction and wear. The end result is flawlessly minted coins. Our customers use our DF drag finishing machines to polish the hub before the minting process, too, because manually polishing each individual workpiece is time-consuming, costly and unreliable.

Contact us today and we can provide a comprehensive and customized processing plan for your needs.

OTEC’s New EPAG-Smart Is Ideal For Smoothing and Polishing Intricate Jewelry

OTEC’s new electropolishing unit, the EPAG-Smart, is perfect for smoothing and high gloss polishing of intricate jewelry. It can polish hard-to-reach inner contours without compromising intricate geometries. Combining reliable machine quality with high cost-effectiveness, the machine can be used to finish stone-set jewelry as well as cast and 3D-printed jewelry. This new generation of machine is also perfect for medium and small production runs.

Processing with the new EPAG-Smart is simple thanks to fast, easy container changes, which allow for faster electrolyte replacement for mechanical finishing of gold and silver. It also offers reproducible processes that are easy to program.

Contact us to learn more.

OTEC’s New SF-HP Is Designed For Heavy and Large Workpieces

OTEC recently expanded its range of stream finishing machines with the addition of the SF-HP, which is designed specifically to accommodate heavier and larger workpieces for industries including aerospace, food, forming tools, machinery construction, energy, oil and gas.

The SF-HP is the world’s first stream finishing machine for workpieces with a diameter and length up to 650 mm and weighing up to 200 kg. Due to the large number of axis settings for the process head and spindle, almost any movement of the workpiece through the process media is possible. This results in precise surface finishing in the shortest possible time, even for the smallest of workpieces. The stream finishing technology provides a green mechanical process without aggressive chemicals. The finishing process improves the tribological surface properties by reducing friction and abrasion.

Prior to the introduction of the SF-HP, OTEC’s SF series machines could only accommodate smaller workpieces up to 350 mm in diameter, 400 mm in length and up to a weight of 60 kg. The new machine also provides an ergonomic solution in the handling of these large and/or heavy workpieces. The customer only needs to place their workpiece into our machine loading area, which can be done with a trolley that is docked to the machine. The loading and unloading of the SF-HP is done with an integrated loading system which picks the work-piece from the loading area, loads it in the processing area and then brings it back again to the load-ing area. In both cases no manual loading of large and/or heavy workpieces is necessary. No robot programming knowledge is needed to program the integrated loading system.

The SF-HP provides the customer with maximum flexibility for workpiece processing. It combines three different drive technologies into one system. With this one system you can either rotate your workpiece at different speeds in one direction, use the step function to place your workpiece at certain angles in the media, or use the pulse finishing technology. Thanks to a large number of axis settings and a flexible process head, you can program almost any workpiece movement through the process media, which guarantees the best possible finishing.

If you’d like to learn more about the SF-HP, please send us a sample processing request.

SHELL ECO-MARATHON: OTEC PRÄZISIONSFINISH PUTS AIRBUS IN POLE POSITION

OTEC Präzisionsfinish GmbH recently collaborated with Airbus’ TED (Technologies et Energies de Demain) team for the Shell Eco-marathon, one of the most notable energy efficiency competitions in the world, where participants are challenged to design a vehicle that can travel further than any others on just one liter of fuel. The Airbus TED team turned to OTEC for targeted surface processing technology that produces a marked improvement in the tribological properties of drive components.

The partnership was sparked by the recommendation of a major automotive manufacturer involved in motorsports. OTEC Präzisionsfinish was brought on to process a variety of components including mechanical precision polishing of gear wheels, crankshafts, camshafts and piston rings to guarantee the indispensably high-quality levels demanded in racing.

Alongside vehicle weight, aerodynamics and tyres, friction plays a decisive role in the drivetrain. The more precisely each relevant component is polished while preserving its geometry, the better its tribological properties – and the lower the friction. And the lower the friction, the further the vehicle can travel on that one liter of fuel.

Marc Denante, a member of the Airbus engine development team shared, “The surface finishing of piston rings and other parts in OTEC machines demonstrably reduces friction in the engine. This becomes visible through reduced fuel consumption while maintaining the same engine performance. After second place with 2.561 km/l consumption in 2019, the goal is now to become the world champion in 2021!”

THE OPTIMAL CUSTOM PROCESS FOR EACH COMPONENT

OTEC Präzisionsfinish has a strong understanding of motorsports and the importance of surface finishing processes and their influence on a workpiece’s tribological properties. In engine, motor and drivetrain components, tribological surface properties are a critical factor in friction and wear behavior and have a huge impact on performance. Changing the surface topography and adapting the surface microstructure for optimal runin are crucial. OTEC’s stream finishing process achieves precisely that, increasing drivetrain efficiency in combustion engines and electric drives.

OTEC also has a long-standing track record in assisting Germany’s Halder Motorsport team. Michelle Halder made history in September 2020 when she became the first female winner of a TCR Europe series race. After a perfect start at the Sunday race in Zolder, Belgium, she left her rivals trailing, maintaining a breathtaking pace right to the finish.

OTEC’s passion and experience led the AIRBUS TED team to choose two OTEC process technologies for their finishing needs.

THE CF-SERIES: OTEC DISC FINISHING

The piston rings for this project were wet-polished in the OTEC CF-Series disc finishing machine, where workpieces are processed in an open container that has a disc-shaped floor with a rotary bearing. Components are added to the fixed container along with a suitable grinding or polishing granulate. When the disc turns, the contents are set in motion in a toroidal flow. Centrifuging the granulate and workpieces makes this process highly intensive.

THE SF-SERIES: PROVEN STREAM FINISHING TECHNOLOGY FROM OTEC

OTEC processed the large, complex components for this project such as camshafts, in our SF-Series stream finishing machine. In this process, which was developed inhouse, the components are clamped in a holder and immersed in a rotating container filled with an abrasive or polishing medium. The workpiece itself is also rotated to produce an even finish. This helps achieve high-quality surfaces even on the most complex geometries, achieving roughness depths of up to Ra 0.01 µm.

To learn more about OTEC’s mass finishing solutions for the automotive industry, send us a sample processing request.