OTEC Präzisionsfinish GmbH recently hosted a webinar on how to select the best media and compounds for a disc finishing process. The webinar shared some of the benefits of choosing the optimal grinding chips and compounds for your process, including shorter processing times and obtaining the desired results more efficiently.

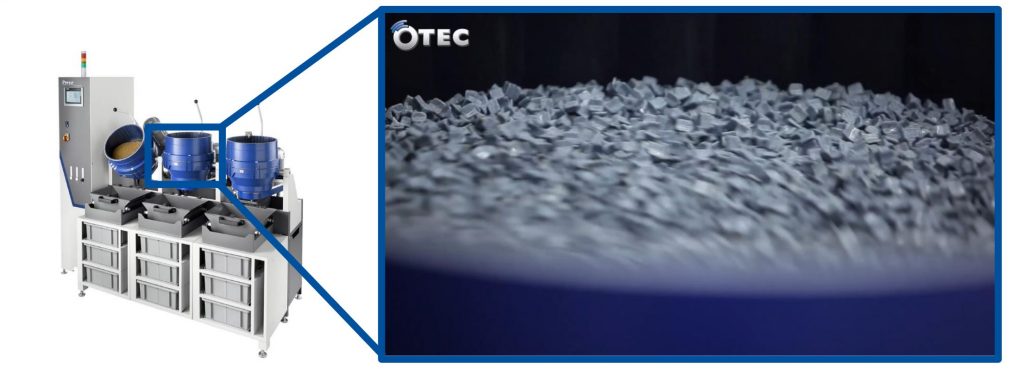

The training also provided an overview of the different media that can be used with disc finishing machines, including plastic, ceramic and porcelain grinding chips. Additionally, during the webinar, best practices for choosing the ideal compounds for wet finishing processes were also discussed.

Possible applications for OTEC’s disc finishing machines include:

- In medical and pharmaceutical manufacturing, for surgical fasteners, bone screws, bone plates and milled parts, ear molds, dental implants and acrylic teeth.

- For the automotive industry, in the manufacturing of pieces including gearbox and engine parts.

- In the jewelry and watchmaking industries, for working parts of mechanical watches and polishing gemstones.

To view this webinar on demand, please reach out to us via our inquiry form.

To see if OTEC can help implement or improve a disc finishing processing for you, please submit a sample processing request.