In the automotive industry, the surface finish of individual components is crucial. So-called bulk goods are typically finished using disc finishing machines whereas sensitive parts that need to be finished to a greater degree of precision require the use of stream finishing or drag finishing machines. At OTEC, we offer a variety of finishing machines that meet the needs of the automotive manufacturing industry to ensure a perfect surface finish and increased service life of components.

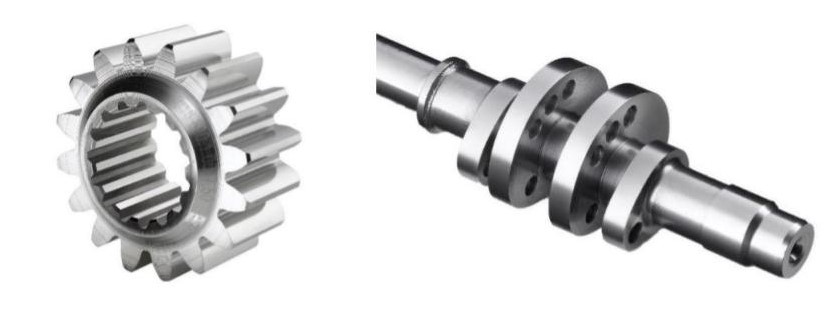

OTEC’s stream finishing machines can be used to process cylindrical or near-cylindrical components – mainly the shell surface. With a wide choice of grinding and polishing media and a host of machine parameter settings, OTEC can provide the perfect process for almost any workpiece including gear wheels, crankshafts, camshafts, valves, spindle drives and other gear-type components.

OTEC’s stream finishing process can help change the surface topography and adapt the surface microstructure of engine, motor and drivetrain component surfaces, contributing to

increased drivetrain efficiency in combustion engines and electric drives. The tribological properties of these engine, motor and drivetrain component surfaces are a critical factor in friction and wear behavior and have a huge impact on their performance. Achieving the perfect finish ensures minimal friction and wear.

Some of the advantages of OTEC’s stream finishing machines include:

- A reduced friction coefficient

- An overall reduction in friction

- Less wear

- Increased internal compressive stress

- A more streamlined production chain since deburring and other techniques can often be replaced by stream finishing

OTEC can develop a custom process designed specifically for your workpiece and application. Please send us a sample processing request if you would like to work with us.