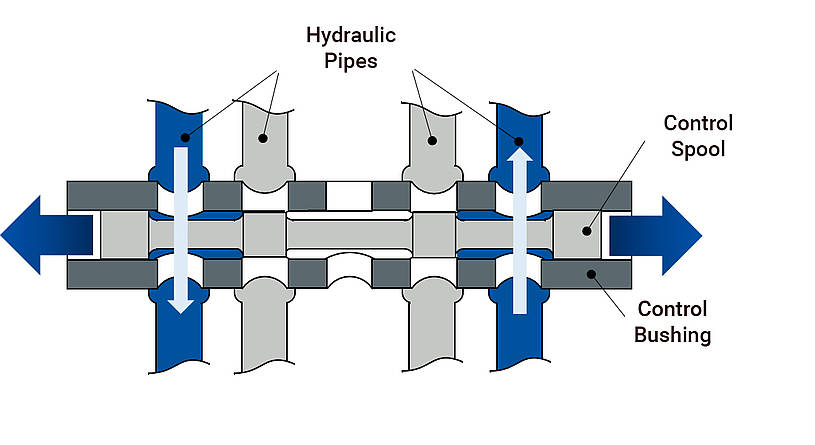

OTEC’s stream finishing machines can be a reliable, quick and cost effective alternative to manual finishing for the aerospace industry. Stream finishing can be used with servo valves, which are commonly used in aircraft flight control systems. These valves hydraulically operate aircraft ailerons, rudders and other control surfaces.

High friction and burr formation among a servo valve’s bushings and spools can lead to abrasion and wear, which can cause the valve to fail. Additionally, sharp or unevenly rounded edges can also impair a valve’s flow. When a servo valve needs to be replaced, it’s very important to guarantee consistency, safety and stability. These replacement parts are frequently post-processed by hand, which can be inefficient and unreliable. Manual processing is subject to human error and can be very time consuming and costly.

However, stream finishing servo valves with a consistent flow of media and strictly monitored parameters guarantees maximum process reliability and repeatability, which means a much lower rejection rate for parts. OTEC’s SF3/3 RLS stream finishing machine with an automatic workpiece loading system can process a component in 40 seconds flat. OTEC machines can pay for themselves in as little as two to three months. The pulse finishing process used with our stream finishing machines reduces cycle time by up to 96% compared to manual processing. Other benefits of OTEC’s high-precision processing include enabling the closest possible tolerance, which is critical for system tightness, and permitting a higher switching or stroke frequency, which significantly increases control accuracy.

Pulse finishing, OTEC’s stream finishing innovation, has remained the fastest mass finishing process on the market since it was launched in 2013, with average process times of 60 seconds. Using very small grinding bodies compatible with the process, it produces precise, effective, ultra-consistent results even with complex workpieces. OTEC stream finishing systems are cost-effective, process-oriented solutions that combine easy automation with maximum process reliability.