Punching dies, like all other punching tools, must meet high demands. A punching die’s surface quality is essential for smooth and efficient stamping, which is why the surface processing methods for these tools are constantly being refined. OTEC offers stream finishing machines and process technology for efficient and optimal surface processing of punching dies.

Stream Finishing For Skiving Cutters

Skiving cutters are used in the production of gear wheels. When producing gear wheels, the desired geometry is achieved by a process known as gear skiving, which combines the two traditional processes of gear hobbing and gear shaping. Skiving offers a high degree of productivity and flexibility, and compensates for the drawbacks of the two traditional processes. Compared to gear shaping, gear skiving significantly reduces processing time. With gear skiving, the axes of the workpiece and tool are not parallel but intersect at an angle. Productivity is proportional to the angle of intersection. When the tool rolls off the workpiece, the relative movement created by this angle is used to achieve the cutting speed. The high relative speeds place great demands on the machine technology used and the spindles of the tool and the workpiece must be synchronized. As an industrial application, skiving has been used for more than a century, but it has taken the development of stable and fully synchronized machines to realize its full potential. Surface treatment is essential to enhance the precision and durability demanded of modern skiving cutters and make the process more efficient.

Read moreOTEC’s EPAG-Smart: The Ideal Solution for Dental Laboratories

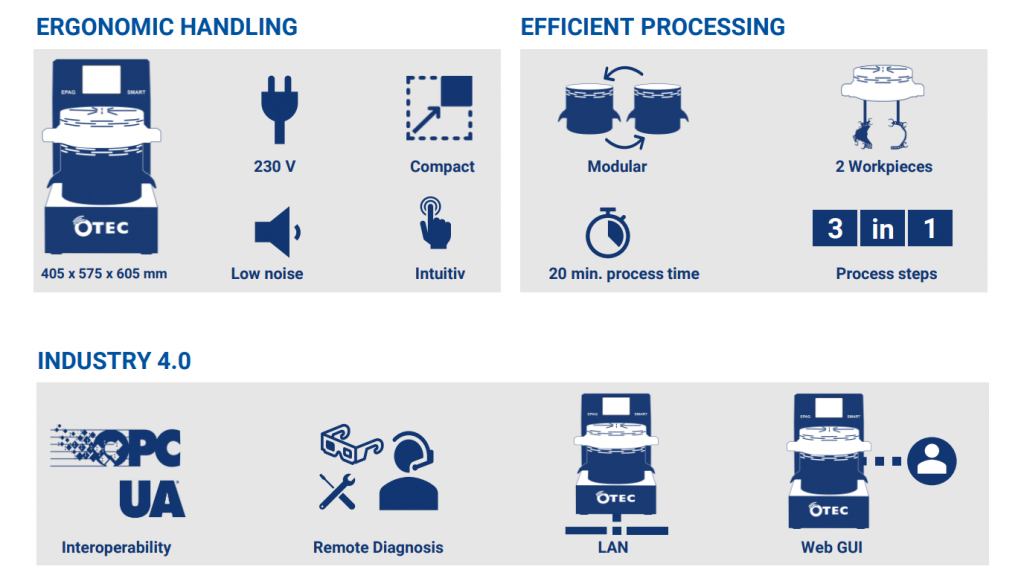

OTEC’s compact electropolishing machine the EPAG-Smart is capable of perfectly smoothing and polishing dental parts in just one step. It’s able to remove the smallest of scratch marks and waviness in a repeatable process without compromising tolerances or geometries.

Some of the benefits of OTEC’s EPAG-Smart include:

- Homogeneous processing even on geometries that are difficult to access

- No deformation because of the single part processing

- Automation reduces processing work by up to 80%

- No compromise on tolerances or geometries

- Repeatable processes

- Combines multiple steps into one process

- Very efficient in terms of processing time and cost

Contact us today to request sample processing of your dental parts.