OTEC’s CF 50 disc finishing machine now boasts a brand new compact design, with an optimized welded structure that guarantees reliable operation and a long service life. The updated design also features storage space for two compound containers and a waste water pumping station with a tray. The optimized spraying system with an additional rinsing nozzle enables process containers with the patented zero gap system to be filled quickly.

Another feature of the new design is a 7.5-inch color touch display for operating the machine that allows users to quickly and easily create, store and retrieve up to 5,000 programs. This makes operation extremely user-friendly. Thanks to the optional remote maintenance function, OTEC can carry out maintenance work on your machine without being onsite. It can also be set up for remote control if required, so you can be flexible in where you control the machine from.

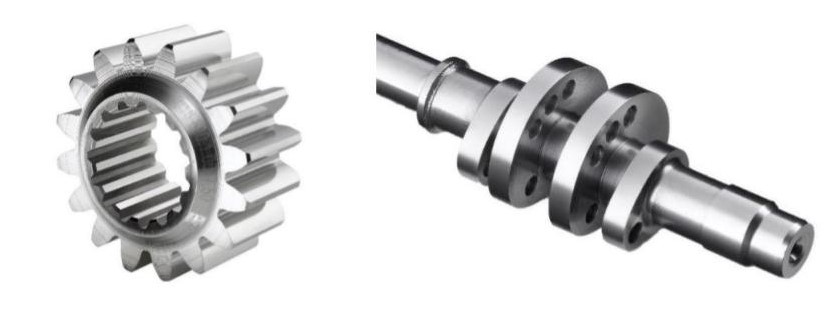

The CF 50 disc finishing machine is suitable for any rapid surface processing requirement involving larger fine blanked, turned, milled and punched parts as well as jewelry.

The OTEC CF Series disc finishing machine is the result of over 20 years of experience and pioneering innovation. Thanks to the optimal design of the containers and gap, our machine provides the ultimate in reliability and short process times.