OTEC Präzisionsfinish GmbH recently collaborated with Airbus’ TED (Technologies et Energies de Demain) team for the Shell Eco-marathon, one of the most notable energy efficiency competitions in the world, where participants are challenged to design a vehicle that can travel further than any others on just one liter of fuel. The Airbus TED team turned to OTEC for targeted surface processing technology that produces a marked improvement in the tribological properties of drive components.

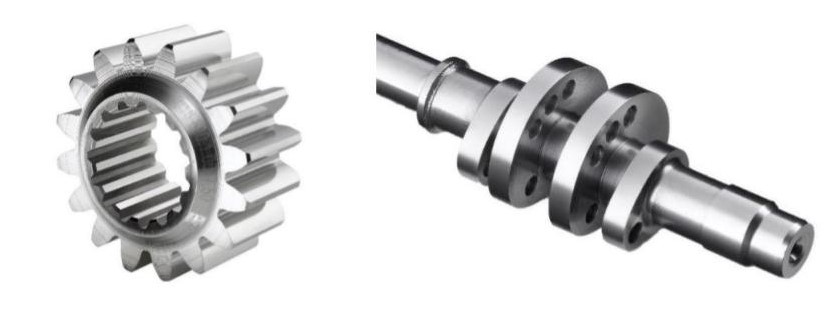

The partnership was sparked by the recommendation of a major automotive manufacturer involved in motorsports. OTEC Präzisionsfinish was brought on to process a variety of components including mechanical precision polishing of gear wheels, crankshafts, camshafts and piston rings to guarantee the indispensably high-quality levels demanded in racing.

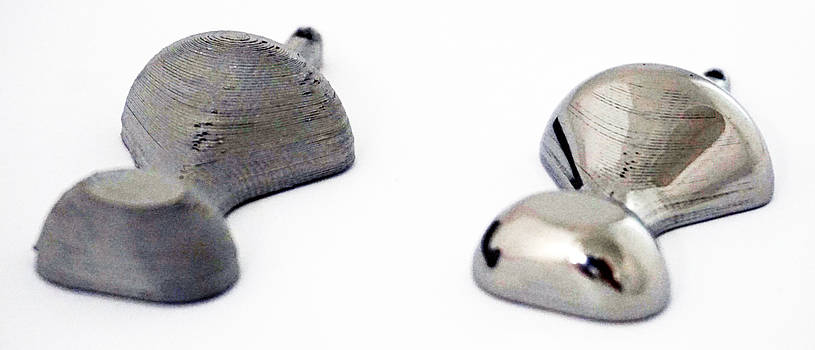

Alongside vehicle weight, aerodynamics and tyres, friction plays a decisive role in the drivetrain. The more precisely each relevant component is polished while preserving its geometry, the better its tribological properties – and the lower the friction. And the lower the friction, the further the vehicle can travel on that one liter of fuel.

Marc Denante, a member of the Airbus engine development team shared, “The surface finishing of piston rings and other parts in OTEC machines demonstrably reduces friction in the engine. This becomes visible through reduced fuel consumption while maintaining the same engine performance. After second place with 2.561 km/l consumption in 2019, the goal is now to become the world champion in 2021!”

THE OPTIMAL CUSTOM PROCESS FOR EACH COMPONENT

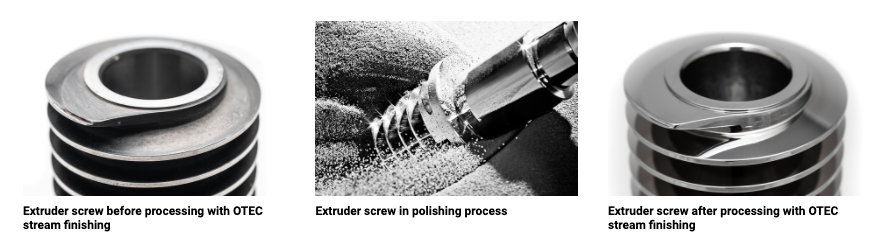

OTEC Präzisionsfinish has a strong understanding of motorsports and the importance of surface finishing processes and their influence on a workpiece’s tribological properties. In engine, motor and drivetrain components, tribological surface properties are a critical factor in friction and wear behavior and have a huge impact on performance. Changing the surface topography and adapting the surface microstructure for optimal runin are crucial. OTEC’s stream finishing process achieves precisely that, increasing drivetrain efficiency in combustion engines and electric drives.

OTEC also has a long-standing track record in assisting Germany’s Halder Motorsport team. Michelle Halder made history in September 2020 when she became the first female winner of a TCR Europe series race. After a perfect start at the Sunday race in Zolder, Belgium, she left her rivals trailing, maintaining a breathtaking pace right to the finish.

OTEC’s passion and experience led the AIRBUS TED team to choose two OTEC process technologies for their finishing needs.

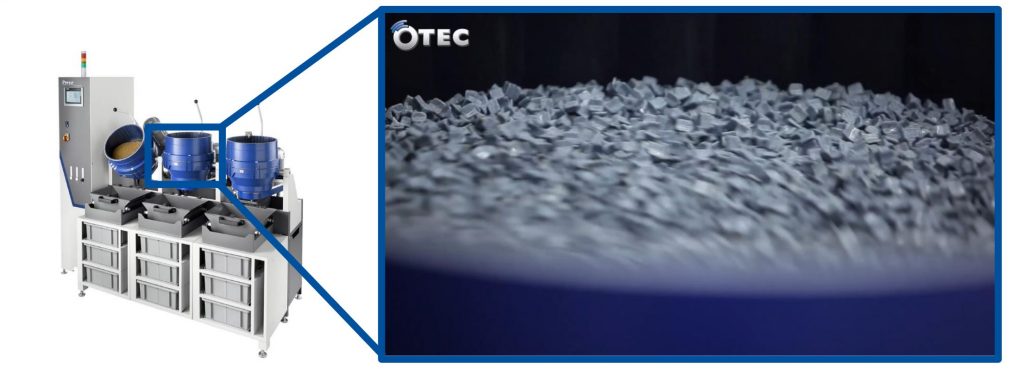

THE CF-SERIES: OTEC DISC FINISHING

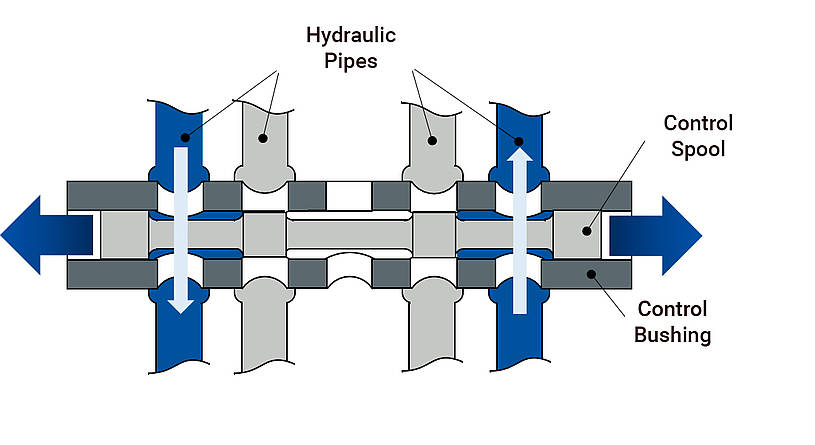

The piston rings for this project were wet-polished in the OTEC CF-Series disc finishing machine, where workpieces are processed in an open container that has a disc-shaped floor with a rotary bearing. Components are added to the fixed container along with a suitable grinding or polishing granulate. When the disc turns, the contents are set in motion in a toroidal flow. Centrifuging the granulate and workpieces makes this process highly intensive.

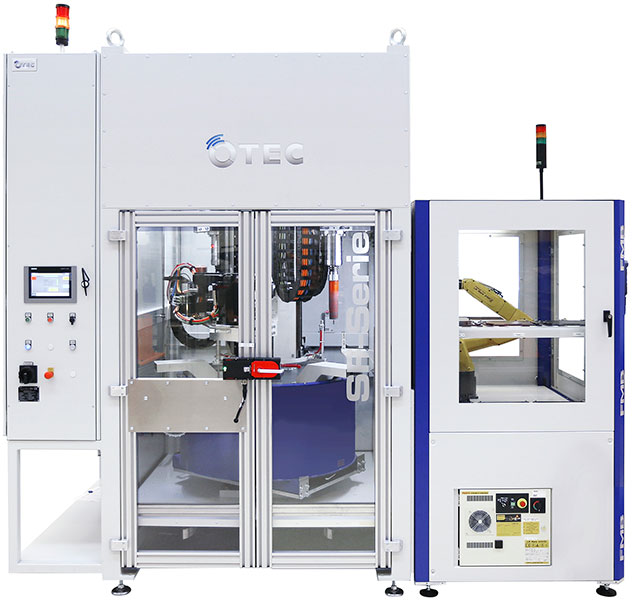

THE SF-SERIES: PROVEN STREAM FINISHING TECHNOLOGY FROM OTEC

OTEC processed the large, complex components for this project such as camshafts, in our SF-Series stream finishing machine. In this process, which was developed inhouse, the components are clamped in a holder and immersed in a rotating container filled with an abrasive or polishing medium. The workpiece itself is also rotated to produce an even finish. This helps achieve high-quality surfaces even on the most complex geometries, achieving roughness depths of up to Ra 0.01 µm.

To learn more about OTEC’s mass finishing solutions for the automotive industry, send us a sample processing request.